Irwin's Safety stands at the forefront of safety and labor solutions within the Mining, Metals, and Minerals sector in Western Canada. Our deep history in this industry shines through our tailored solutions applied to maintenance and capital projects.

Irwin's commitment to excellence is reflected in our ability to provide tailored integrated services that meet the unique needs of each client. These services include:

Our talented labourers have the experience, work ethic, and safety-first mindset needed to get your Mill, Shovel, Drill, or Ball Mill up and running more efficiently so that you can minimize downtime and focus on producing. Some of our areas of expertise include

Whether you are looking to contract Mine Rescue services from an experienced emergency services provider to augment your team, develop internal mine rescue teams to become self-sufficient, or test/audit/drill your established Mine Rescue team through simulated exercises - Irwin's Safety is there for you. With technical emergency response expertise that meets the mines act standard, we supply, train, and drill Mine Rescue services so you can ensure your emergency response system is best-in-class. Our Emergency Response Services include

Irwin's has a team of professional consultants ready to make sure your Health and Safety Management System meets or exceeds the Mines Act standard. From process design and implementation, to boots-on-the-ground support, our team is filled with subject-matter-experts that can benefit you with:

With over 100 different courses to offer, Irwin's is your trusted partner to make sure your workers have the confidence and skills to do the job right. Our courses are recognized by certifying bodies that are best-in-class for industry standards. Equipment Operation, Rescue, First Aid are just a few of the many categories of training that we have to offer through several different delivery models:

When it comes to working in dangerous environments, your crews need the equipment in safe to keep them protected. Irwin's asset management and quality control system ensures that our customers are equipped with the right tools to keep them out of the line of fire. Our equipment specialty includes:

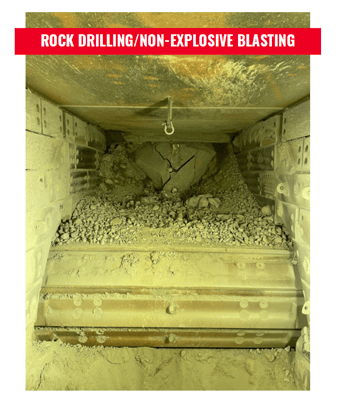

The picture on the left shows a large boulder that is stuck in the reclaim feeder. We took a rock drilling bit that‘s 1' ½ in diameter and drilled multiple holes through the rock. Then, we filled those with an expansive demolition grout. Within 12hrs, the boulder fractured and could be removed with just walking the conveyor. This process saves time on not daylighting the feeder to remove the rock from above and not shutting down the secondary feeders to the sag mill. This job can be completed within 24 hrs using this method.

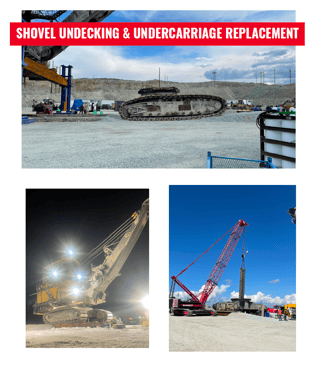

These pictures show shovel undecking andundercarriage replacement jobs at the Gibraltar mine. Komatsu shovel and a Bucyrus shovel are pictured. With 30 days of scope, we cleaned all components of the shovel so that they could be removed and installed with ease for the rebuild. Cleaners also identified cracks and issues with the shovels for the customer/client so that they could get addressed atthe time of rebuild. We also provided spark watch and hole watch for the customer.

These pictures show shovel undecking andundercarriage replacement jobs at the Gibraltar mine. Komatsu shovel and a Bucyrus shovel are pictured. With 30 days of scope, we cleaned all components of the shovel so that they could be removed and installed with ease for the rebuild. Cleaners also identified cracks and issues with the shovels for the customer/client so that they could get addressed atthe time of rebuild. We also provided spark watch and hole watch for the customer.

“The safety of the people shall be the highest law."

– Marcus Tullius Cicero, Roman philosopher born in 106 BC